- bhavya gada

- No Comments

Protecting your home’s foundation from water damage is critical, especially in areas like Maryland, where heavy rainfall, freeze-thaw cycles, and high groundwater levels are common. Flood-resistant coatings are a practical way to safeguard against structural damage, mold growth, and costly repairs. Here’s a quick rundown of the top options:

- Rub-R-Wall Liquid Rubber: High flexibility (up to 1,200% elongation), strong hydrostatic resistance (15 psi), and a lifespan of 20–25 years.

- Polyguard 650 Membrane: Self-adhesive sheet with excellent water pressure resistance (15 psi) and self-healing properties.

- DRYLOK Extreme Masonry Paint: Budget-friendly, DIY-friendly, and rated for 15 psi hydrostatic pressure with a 15-year warranty.

- Hydro-Seal 75 Acrylic Elastomeric Coating: Balances water resistance and breathability, great for managing seasonal shifts.

- Volclay Bentonite Panels: Clay-based panels that self-seal upon contact with water, ideal for extremely wet conditions.

Each product has its strengths, from flexibility to vapor permeability, and choosing the right one depends on your foundation’s specific needs and Maryland’s unique climate challenges.

Quick Comparison

| Product | Type | Hydrostatic Resistance | Flexibility | Lifespan | Best Use Case |

|---|---|---|---|---|---|

| Rub-R-Wall | Liquid rubber | Up to 15 psi | Up to 1,200% | 20–25 years | Clay soils, freeze-thaw cycles |

| Polyguard 650 | Sheet membrane | Up to 15 psi | Self-healing | 20+ years | High water tables, new construction |

| DRYLOK Extreme | Paint-based masonry coating | Up to 15 psi | Semi-rigid | 15 years | DIY, existing foundations |

| Hydro-Seal 75 | Acrylic elastomeric coating | 10–15 psi typical | Up to 27.5 mils | 15–20 years | Above-grade, breathable protection |

| Volclay Bentonite | Clay-based panel system | Up to 15 psi | Self-sealing | 20+ years | Extremely wet conditions |

Professional installation is highly recommended for most options to ensure proper application and long-term performance. Maryland homeowners can consult local experts like Pro Landscapes MD for tailored solutions that combine coatings with effective drainage systems.

Waterproofing Basement Walls with DRYLOK® Paint — by Home Repair Tutor

What to Look for in Flood-Resistant Foundation Coatings

Foundation coatings aren’t all the same, and selecting the right one is essential to protect your Maryland home from water damage. With Maryland’s frequent flooding and freeze-thaw cycles, understanding key performance factors is critical.

Hydrostatic Pressure Resistance is a must-have. When heavy rains saturate the ground, water pressure builds up against your foundation walls. To withstand this, a coating should handle at least 10–15 psi of hydrostatic pressure – comparable to the force from a 23–35-foot column of water[1]. Cheaper options often fail under such pressure, leading to leaks and even structural issues.

Flexibility and Crack-Bridging are equally important, especially in Maryland’s shifting climate. Freeze-thaw cycles and soil movement can cause cracks in foundations. High-quality liquid rubber coatings can stretch up to 1,200% – and some even up to 1,800% – to maintain a watertight seal despite these movements[1].

Chemical Resistance and UV Protection add another layer of defense. Top-tier coatings resist damage from soil contaminants, salts, and other chemicals. UV-resistant formulations are also crucial for areas exposed to sunlight, keeping the coating intact and preventing discoloration over time[1].

Vapor Permeability ensures your foundation stays dry while allowing trapped moisture vapor to escape. This balance prevents mold growth and structural issues. High-quality acrylic elastomeric coatings typically offer around 12 perms, striking the right balance between blocking liquid water and allowing vapor to pass through[1].

Longevity determines how long your investment lasts. Premium coatings provide protection for 20–25 years, with some advanced systems boasting lifespans exceeding 100 years. Durability against UV rays, chemicals, freeze-thaw cycles, and physical wear all contribute to a coating’s lifespan[1].

| Feature | Dampproofing | True Waterproofing |

|---|---|---|

| Water Resistance | Moisture vapor only | Blocks liquid water under pressure |

| Hydrostatic Pressure | None/minimal | Rated up to 15 psi |

| Flexibility | Low | High (up to 1,800% elongation) |

| Longevity | Shorter lifespan | 20–100+ years |

| Application | Basic asphalt coatings | Liquid rubber, advanced membranes |

This table highlights the differences between dampproofing and true waterproofing, helping Maryland homeowners make informed decisions.

Dampproofing uses basic asphalt-based coatings that only resist moisture vapor, while true waterproofing employs advanced materials designed to block both liquid water and vapor under pressure[1][2]. In Maryland’s challenging conditions – frequent storms, high water tables, and freeze-thaw cycles – true waterproofing is essential.

When choosing a product, don’t just rely on marketing claims; look for proven performance data. For example, DRYLOK Extreme Masonry Waterproofer is rated for 15 psi and comes with a 15-year warranty, showcasing its reliability[4].

Finally, local expertise is invaluable. Maryland’s unique soil, drainage issues, and weather patterns require tailored solutions. Experienced professionals familiar with the region can recommend and apply the best coating system for your home, ensuring maximum protection and effectiveness.

1. Rub-R-Wall Liquid Rubber Waterproofing Membrane

Rub-R-Wall is a spray-applied liquid rubber designed to create a seamless, uniform waterproof barrier for foundations. Unlike traditional sheet membranes or basic coatings, this system offers complete coverage, even around tricky areas like pipes, corners, and irregular surfaces – something many older methods struggle to achieve. Since it requires specialized equipment and licensed professionals for installation, Rub-R-Wall is considered a high-grade solution. Once applied, it cures into a flexible membrane that moves with your foundation, adapting to soil shifts and seasonal changes. This flexibility plays a key role in its ability to handle pressure and maintain performance.

Hydrostatic Pressure Resistance

Rub-R-Wall is built to handle intense conditions, resisting hydrostatic pressures of over 3.5 psi – equivalent to water columns more than 8 feet high. This ensures the barrier remains intact, even when exposed to prolonged pressure. [8]

Flexibility and Crack-Bridging

One of Rub-R-Wall’s standout features is its flexibility. It can bridge hairline cracks up to 1/16 inch, accommodating minor foundation settling without compromising its waterproofing. This elastomeric property allows it to stretch and adjust during freeze-thaw cycles, which are common in Maryland. This ensures dependable protection through changing seasons. [8] [6]

Longevity and Durability

Rub-R-Wall is built to last, offering a 20-year warranty and resistance to UV rays, chemicals, and general wear. When applied correctly, it delivers long-term durability with minimal need for repairs. Its performance holds steady across Maryland’s varying climate, maintaining flexibility from the coldest winters to the hottest summers. [8]

2. Polyguard 650 Waterproofing Membrane

When it comes to flood protection, Polyguard 650 stands out with its thick, self-adhesive membrane. Manufactured in 60–65 mil thicknesses, it combines a cross-laminated polyethylene backing with rubberized asphalt for direct application to concrete, CMU, and similar surfaces. Installation is straightforward, thanks to wide-format sheets up to 48 inches for large areas, along with narrower sheets designed for corners and joints.

Hydrostatic Pressure Resistance

Polyguard 650 is built to handle significant water pressure, resisting hydrostatic pressures of up to 15 psi. This makes it a strong choice for foundations in areas prone to high groundwater or severe flooding. For instance, during a 100-year flood event, homes protected with Polyguard 650 avoided basement flooding entirely, while untreated structures sustained water damage [5].

Flexibility and Crack-Bridging

One of the standout features of Polyguard 650 is its ability to self-heal, bridging cracks up to 1/16 inch and maintaining a seamless waterproof barrier. This flexibility is especially important for foundations that shift seasonally. In projects with expansive clay soils, the membrane has proven effective even when small cracks appeared, keeping water out and minimizing structural risks [1][5]. Alongside its crack-bridging capabilities, it also manages moisture effectively through controlled vapor movement.

Vapor Permeability (Breathability)

Polyguard 650 is designed to block liquid water while allowing controlled moisture vapor movement. This balance prevents moisture buildup within concrete, reducing the chances of mold, efflorescence, and material deterioration. This feature is particularly valuable in humid environments or areas with varying groundwater levels, ensuring the foundation stays dry and sound [1][9].

Longevity and Durability

Beyond its immediate performance, Polyguard 650 is built for the long haul. When installed and maintained correctly, it offers an expected lifespan of 20–25 years. Case studies from homes in the Northeastern U.S. highlight its durability, showing minimal wear even after 15 years in regions with harsh winters and frequent flooding. The 650 PRM variant further simplifies the process by eliminating the need for a separate protection course, making installation easier and extending the membrane’s life [1][5].

3. DRYLOK Extreme Masonry Waterproofing Paint

DRYLOK Extreme Masonry Waterproofing Paint is a reliable option for homeowners looking to protect their property from flooding. This latex-based, semi-impermeable coating can be applied with standard tools, making it a practical choice for both DIY enthusiasts and professionals. Let’s take a closer look at how it performs under challenging conditions.

Hydrostatic Pressure Resistance

This coating is designed to withstand 15 psi of hydrostatic pressure, which is equivalent to the force exerted by a 33-foot column of water. That’s far beyond what most residential basements face, even during severe flooding events[4]. Its ASTM D-7088 certification further highlights its dependable performance in both above-ground and below-ground applications.

Flexibility and Crack-Bridging

DRYLOK Extreme incorporates flexible polymers that allow it to handle minor foundation shifts and seal small cracks. While it doesn’t offer the same level of flexibility as liquid rubber membranes, its polymer-enhanced formulation is effective at preventing water from sneaking through hairline cracks in concrete or masonry.

Vapor Permeability

With a vapor permeability rating of less than 1 perm, DRYLOK Extreme effectively blocks both liquid water and water vapor. However, because it can trap existing moisture, it’s best to pair this coating with proper drainage and ventilation – especially in humid or moisture-prone areas. For instance, exterior drainage systems like those from Pro Landscapes MD can complement this coating to manage moisture more effectively.

Longevity and Durability

Backed by a 15-year transferable warranty, DRYLOK Extreme is built to last. It resists mildew on the dry surface and can endure harsh weather, including winds up to 140 mph – equivalent to a Category 4 hurricane. It also helps reduce radon gas infiltration. With a coverage rate of 75–100 square feet per gallon and a price range of $35–$45 per gallon, applying at least two coats ensures long-term protection at a reasonable cost.

sbb-itb-843f8be

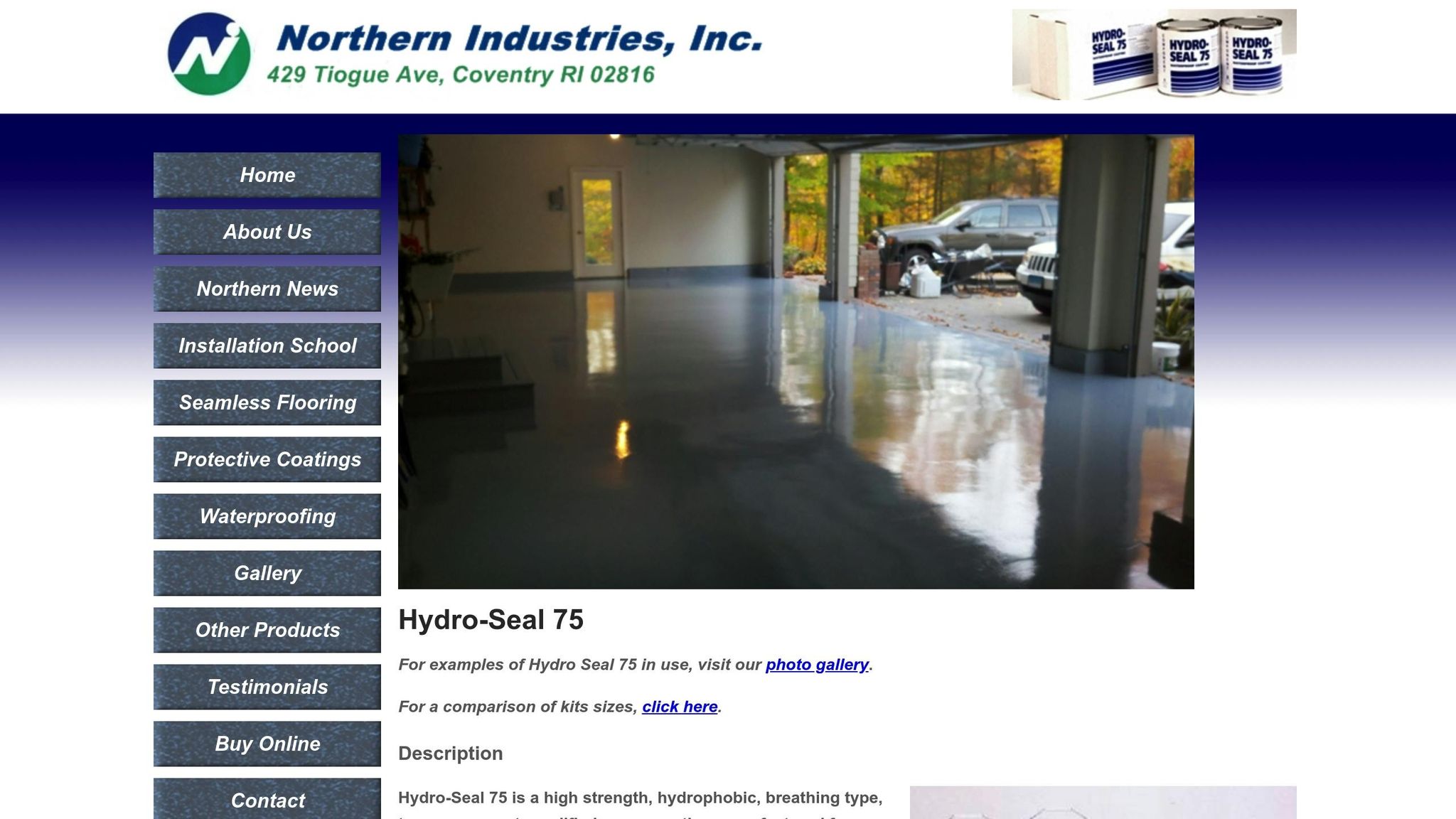

4. Hydro-Seal 75 Acrylic Elastomeric Coating

Hydro-Seal 75 is a water-based acrylic elastomeric sealer designed to protect foundations effectively. It strikes a balance between water resistance and breathability, making it a practical choice for managing Maryland’s unpredictable weather conditions. Its waterproofing properties, combined with flexibility, make it a reliable option for foundation protection.

Hydrostatic Pressure Resistance

Although Hydro-Seal 75’s specific hydrostatic pressure rating isn’t disclosed, acrylic elastomeric coatings typically handle pressures in the 10–15 psi range. This level of resistance is sufficient to manage common groundwater pressures and water intrusion caused by storms in residential foundations. [1]

Flexibility and Crack-Bridging

Hydro-Seal 75 adapts to temperature changes, which is critical for addressing seasonal foundation shifts. It bridges cracks up to 27.5 mils at 73°F, 19.5 mils at 32°F, and 12 mils at –77°F. This flexibility helps protect the foundation from damage caused by concrete expansion and contraction during freeze-thaw cycles. Its ability to bridge cracks also supports controlled moisture regulation. [1]

Vapor Permeability

With a vapor permeability rating of 12 perms, Hydro-Seal 75 allows moisture vapor to escape while preventing water from entering. This balance ensures effective moisture management for foundations. [1]

Longevity and Durability

Hydro-Seal 75 is built to last. Its low-odor, low-VOC formula makes it suitable for indoor basement applications, while its UV stability ensures it performs well on above-grade surfaces exposed to sunlight. The water-based formula allows for easy application using a brush, roller, or sprayer, and cleanup is as simple as using soap and water. When applied at a thickness of 16–20 mils, it delivers durable, flexible protection. [1]

For homeowners dealing with moisture-prone basements – a reality for about 60% of U.S. homes – Hydro-Seal 75 offers a strong combination of waterproofing and breathability. This makes it an effective solution for both immediate flood resistance and long-term foundation protection. [1]

5. Volclay Bentonite Waterproofing Panels

Volclay Bentonite Waterproofing Panels take a different approach compared to liquid-applied systems by using a physical barrier. These panels are constructed by sandwiching sodium bentonite clay between durable materials, making them highly effective for foundations exposed to heavy moisture.

When water comes into contact with the bentonite clay, it swells dramatically. This swelling creates a self-sealing, impermeable barrier that naturally fills cracks and gaps when installed against foundation walls. The result? Strong flood resistance achieved through a passive, self-expanding process.

Hydrostatic Pressure Resistance

One of the standout features of these panels is how they handle water pressure. The bentonite clay’s swelling action increases in efficiency as water pressure rises. This makes the panels particularly useful in areas with high groundwater levels or frequent flooding, where reliable waterproofing is essential.

Flexibility and Crack-Bridging

The swelling properties of bentonite clay also shine when it comes to flexibility. As the clay expands upon contact with moisture, it can adapt to minor shifts or movements in the foundation. This ensures the waterproofing remains intact, even if the foundation develops small cracks over time.

Vapor Barrier Protection

These panels are completely vapor-impermeable, blocking all water vapor from passing through. This creates a strong moisture barrier, offering excellent protection in extremely wet conditions. However, it’s worth noting that this level of impermeability may reduce the breathability of the foundation compared to more permeable solutions.

Longevity and Durability

Volclay Bentonite Panels are built to last. When installed correctly, they can provide waterproofing for the lifetime of the structure. Even if minor damage occurs, the self-healing properties of the bentonite clay ensure the barrier restores itself automatically.

Proper installation is critical for these panels to perform as intended. They must be placed tightly against the foundation wall, with seams carefully overlapped and sealed. Backfilling should be done cautiously to avoid any damage. For Maryland homeowners dealing with persistent moisture issues, working with local professionals like Pro Landscapes MD can ensure a flawless installation and long-term performance.

Product Comparison Chart

When selecting the best flood-resistant coating for your Maryland foundation, it’s essential to weigh key specifications. Each product shines in different areas, depending on your home’s needs and the unique local conditions.

| Product | Type | Hydrostatic Resistance | Flexibility | Expected Lifespan | Best For Maryland Homes |

|---|---|---|---|---|---|

| Rub-R-Wall Liquid Rubber | Liquid-applied elastomeric coating | Up to 15 psi | Up to 1,200% elongation | 20–25 years | Excellent for clay soils and freeze–thaw cycles |

| Polyguard 650 Membrane | Sheet membrane (60–65 mil) | Up to 15 psi | Flexible with self-healing properties | 20+ years | Ideal for new construction and areas with high water tables |

| DRYLOK Extreme | Paint-based masonry coating | Up to 15 psi guaranteed | Semi-rigid | 15-year warranty | Great for existing foundations and DIY application |

| Hydro-Seal 75 Acrylic | Acrylic elastomeric paint | 10–15 psi typical | Up to 27.5 mils crack bridging | 15–20 years | Perfect for breathable protection and above-grade use |

| Volclay Bentonite Panels | Clay-based panel system | Up to 15 psi optimal | Swells upon contact with moisture | 20+ years | Best for extremely wet conditions and high pressure |

This chart breaks down how these products handle Maryland’s common flooding challenges. Hydrostatic pressure ratings are a key factor, showing how well each option can resist water pressure. Products rated at 15 psi are particularly effective for areas with severe flooding or high groundwater levels.

Flexibility and crack-bridging capabilities are equally important, especially given Maryland’s freeze–thaw cycles. For example, Rub-R-Wall Liquid Rubber boasts up to 1,200% elongation, making it a standout choice for foundations that experience movement due to temperature changes.

When comparing costs, paint-based coatings are typically the most budget-friendly, ranging from $1–$2 per square foot. Liquid rubber and sheet membranes, though more expensive at $2–$4 per square foot, deliver superior durability and protection, making them a worthwhile investment for Maryland’s demanding climate.

Considering the region’s heavy spring rains, humid summers, and freeze–thaw conditions, liquid rubber and sheet membranes offer the most comprehensive protection. Their combination of high hydrostatic resistance, flexibility, and long lifespan ensures reliable performance in even the toughest conditions.

For sheet membranes and bentonite panels, professional installation is essential. Local experts, like Pro Landscapes MD, specialize in addressing Maryland’s specific soil and drainage challenges, ensuring your system is installed for maximum effectiveness. Choosing the right product and professional installation strengthens your foundation’s defense against water damage.

Professional Installation and Local Expertise

Getting flood-resistant coatings installed correctly is critical. The difference between a coating that lasts decades and one that fails in just a few years often comes down to professional installation. In fact, improper installation is a leading cause of water intrusion issues – accounting for up to 70% of construction litigation related to water problems, according to industry data[1].

Applying these coatings isn’t just about slapping them on a surface. It requires precise preparation, the right application thickness, and proper integration with drainage systems. Professional installers use specialized equipment to ensure even coverage and can spot potential trouble areas that an untrained eye might miss. This attention to detail is especially important in Maryland, where the climate poses unique challenges like freeze-thaw cycles, clay-heavy soils, and seasonal flooding. For instance, liquid rubber coatings need to be applied under specific temperature and humidity conditions to achieve their full stretch capacity of 1,200%.

Surface preparation is another area where professional expertise makes all the difference. Before applying a coating, the foundation must be thoroughly cleaned, cracks repaired, and sometimes a primer applied. Skipping these steps – common in DIY projects – leads to poor adhesion and early failure. Professionals are also skilled at handling tricky spots like foundation joints, pipe penetrations, and corners, which are common entry points for water.

Pro Landscapes MD stands out in central Maryland for its expertise in foundation protection. Their team combines advanced coating applications with effective drainage solutions to provide long-lasting results. From Ellicott City to Bethesda, they understand how Maryland’s unique soil and weather conditions impact waterproofing. Their drainage solutions, such as French drains and proper grading, work alongside coatings to significantly reduce water intrusion – by as much as 80% in flood-prone areas[5].

What sets Pro Landscapes MD apart is their team, which includes professional horticulturists with formal training in landscape design. This ensures they approach foundation protection with both technical precision and an understanding of the surrounding environment. They serve a wide area, including Howard, Montgomery, Carroll, Frederick, Prince George’s, and Baltimore counties, tailoring their services to meet the specific needs of each location.

Another major advantage of professional installation is the warranty protection it provides. For example, when DRYLOK Extreme is installed by certified professionals, it comes with a fully transferable 15-year warranty[3]. This not only protects your investment but also gives you peace of mind, knowing you’ll have support if any issues arise.

While professional installation costs typically range from $5 to $15 per square foot, the benefits far outweigh the expense. Proper installation ensures better performance and longer life for your coating, saving you from costly foundation repairs caused by water damage. Plus, many professional installers offer ongoing maintenance services, catching potential issues early and extending the life of your coating.

When it comes to flood protection, professional installation and local expertise are essential pieces of the puzzle. Choosing professionals means you’re investing in the long-term health of your foundation, rather than gambling on a DIY solution. With Maryland’s challenging weather and soil conditions, the combination of expert techniques, local knowledge, and integrated drainage systems provides the reliable defense your foundation needs to stand strong against flood damage.

Conclusion

Flood-resistant coatings play a crucial role in protecting your foundation and the investment tied to it. These coatings shield your foundation from hydrostatic pressure, freeze-thaw cycles, and chemical exposure, reducing risks and safeguarding structural integrity [1][11]. For example, liquid rubber systems can stretch up to 1,200%, bridging cracks and lasting 20–25 years – or even longer with products like Rub-R-Wall [1][6][7]. This impressive durability highlights the importance of selecting a coating that suits your foundation’s specific requirements.

When it comes to Maryland’s unpredictable weather and diverse soil conditions, choosing the right product becomes even more essential [1]. DRYLOK Extreme, for instance, offers resistance to hydrostatic pressure up to 15 psi and comes with a transferable 15-year warranty [3]. Liquid rubber systems, on the other hand, provide the flexibility needed for foundations prone to movement. The key is to match the coating’s features to your local environment and the unique demands of your foundation.

In Maryland, professional installation is critical to ensuring long-term success. Proper preparation and application not only extend the life of the coating but also maximize its effectiveness. Pro Landscapes MD, based in central Maryland, excels at combining advanced coating applications with drainage solutions tailored to the region’s specific challenges. Their comprehensive approach addresses both immediate protection and long-term durability by effectively managing water around your property.

Investing in high-quality coatings and expert installation can save on future repair costs while also improving indoor air quality [10]. These systems protect your property’s structural integrity and value, giving you peace of mind that your foundation is equipped to handle whatever nature throws its way.

Your foundation is the backbone of your home’s stability and value. By choosing and properly installing a flood-resistant coating, you’re ensuring decades of dependable protection and performance.

FAQs

What’s the best way to choose a flood-resistant coating for my foundation in Maryland?

When it comes to selecting the best flood-resistant coating for your foundation, there are a few key factors to consider. These include the type of foundation your home has, the climate in your area, and how much water exposure your property typically experiences. For homeowners in Maryland, Pro Landscapes MD offers specialized advice that takes into account the region’s specific weather patterns and soil characteristics. Their experienced team focuses on drainage solutions and foundation protection, helping to keep your home secure and dry year-round.

Why is professional installation better than DIY for flood-resistant coatings?

Hiring professionals to apply flood-resistant coatings ensures they’re done right, offering the best protection for your foundation. Trained experts have the skills and equipment to tackle challenges like uneven surfaces or sealing issues that could weaken the coating’s effectiveness.

Beyond proper application, professionals can guide you toward the right products tailored to your needs and local conditions, which can save you both time and hassle. Choosing expert installation means a more durable result and the confidence of knowing the job was handled correctly.

Why are hydrostatic pressure resistance and flexibility important for foundation coatings in flood-prone areas?

When it comes to foundation coatings in flood-prone areas, hydrostatic pressure resistance is a game-changer. This feature acts as a barrier, stopping water from forcing its way through the foundation, even under intense pressure from heavy rains or flooding. By keeping water out, these coatings help protect the structural integrity of your home.

Another key factor is flexibility. A flexible coating can adjust to small shifts or tiny cracks in the foundation without breaking its protective seal. This adaptability ensures the coating remains effective over time, which is especially valuable in areas where soil tends to move or settle. Together, these qualities provide a dependable defense against water damage.

Chat with Us